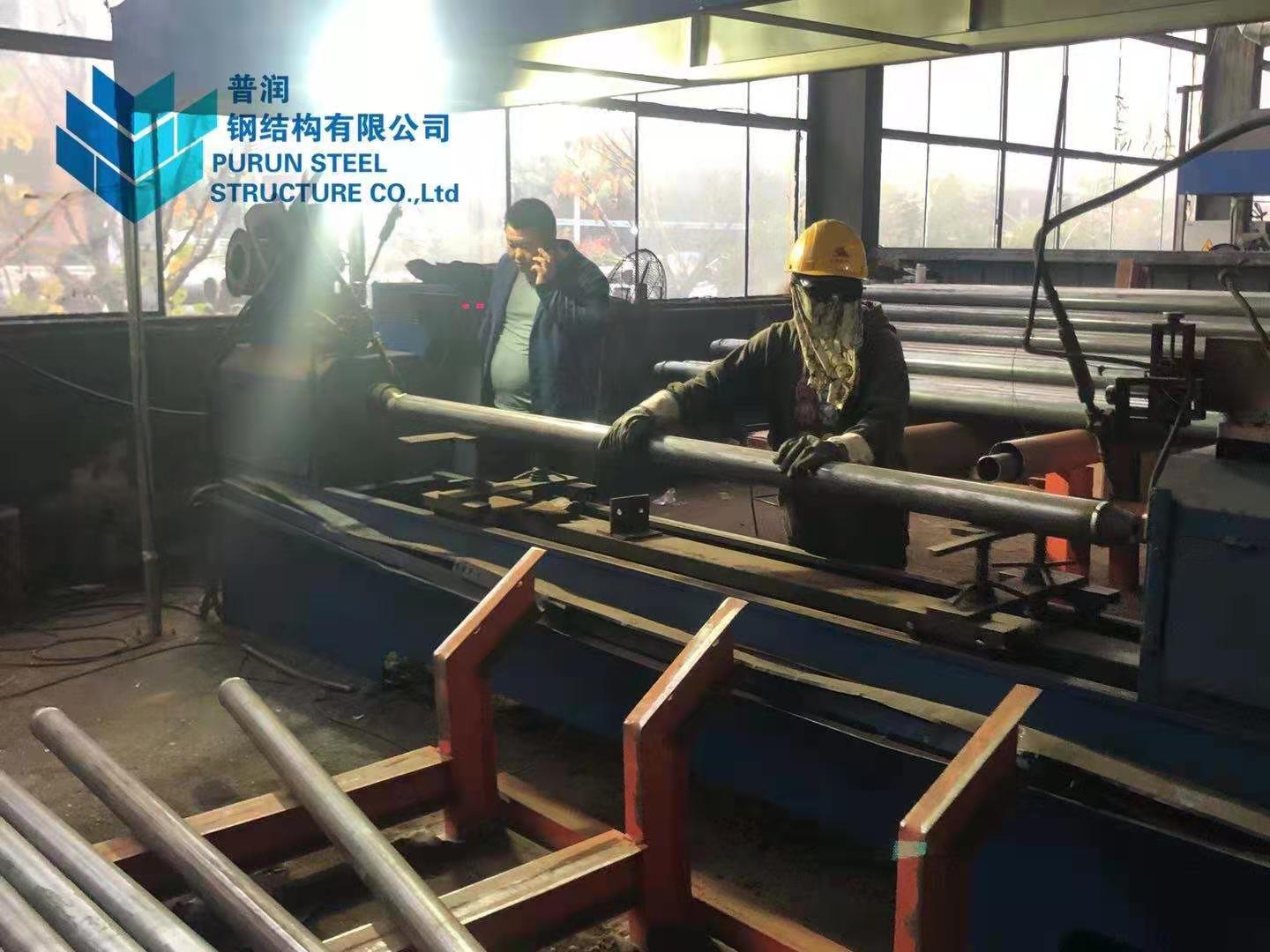

New Fashion Design for Space Frame Beam - Welding procedure of steel space frame – Puye

New Fashion Design for Space Frame Beam - Welding procedure of steel space frame – Puye Detail:

welding:

The welding process is an important process in the production of the steel space frame, and it must be carried out in strict accordance with the welding operation instructions. Minimize the residual stress caused by welding, and timely correct the deformation by means of flame heating.

A. When the steel pipe is welded with the sealing plate and the steel pipe, the groove shall be opened according to the requirements, and the groove angle shall meet the requirements of the angle formed between the electrode and the groove surface to avoid unfusion and slag inclusion. In addition, the groove gap should be Large enough so that the electrode arc can reach the bottom of the groove and avoid insufficient penetration depth.

B. Avoid setting the welding seam to the middle of the rod when the steel pipe is butted.

C. Matters needing attention in welding operation:

a. During manual arc welding, the conveying range should not be too large, and multi-pass and multi-layer welding is used.

During the process, the weld bead or interlayer welding slag, slag inclusion, oxide, etc. should be strictly removed. Grinding wheel, steel can be used.

Tools such as wire brushes.

b. The same welding seam should be welded continuously and completed at one time.

c. For various weld joints, after the welding is completed, the slag and metal spatter on the surface of the weld should be cleaned up.

Check the appearance quality of the weld, and there must be no depression, weld bead, undercut, blowhole, lack of fusion, crack

and other defects exist.

d. After the butt weld is welded, ultrasonic flaw detection should be carried out after 24 hours.

Product detail pictures:

Related Product Guide:

We are experienced manufacturer. Wining the majority of the crucial certifications of its market for New Fashion Design for Space Frame Beam - Welding procedure of steel space frame – Puye , The product will supply to all over the world, such as: Vancouver, Croatia, French, The company has numbers of foreign trade platforms, which are Alibaba,Globalsources,Global Market,Made-in-china. "XinGuangYang" HID brand products sell very well in Europe, America, Middle East and other regions more than 30 countries.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.