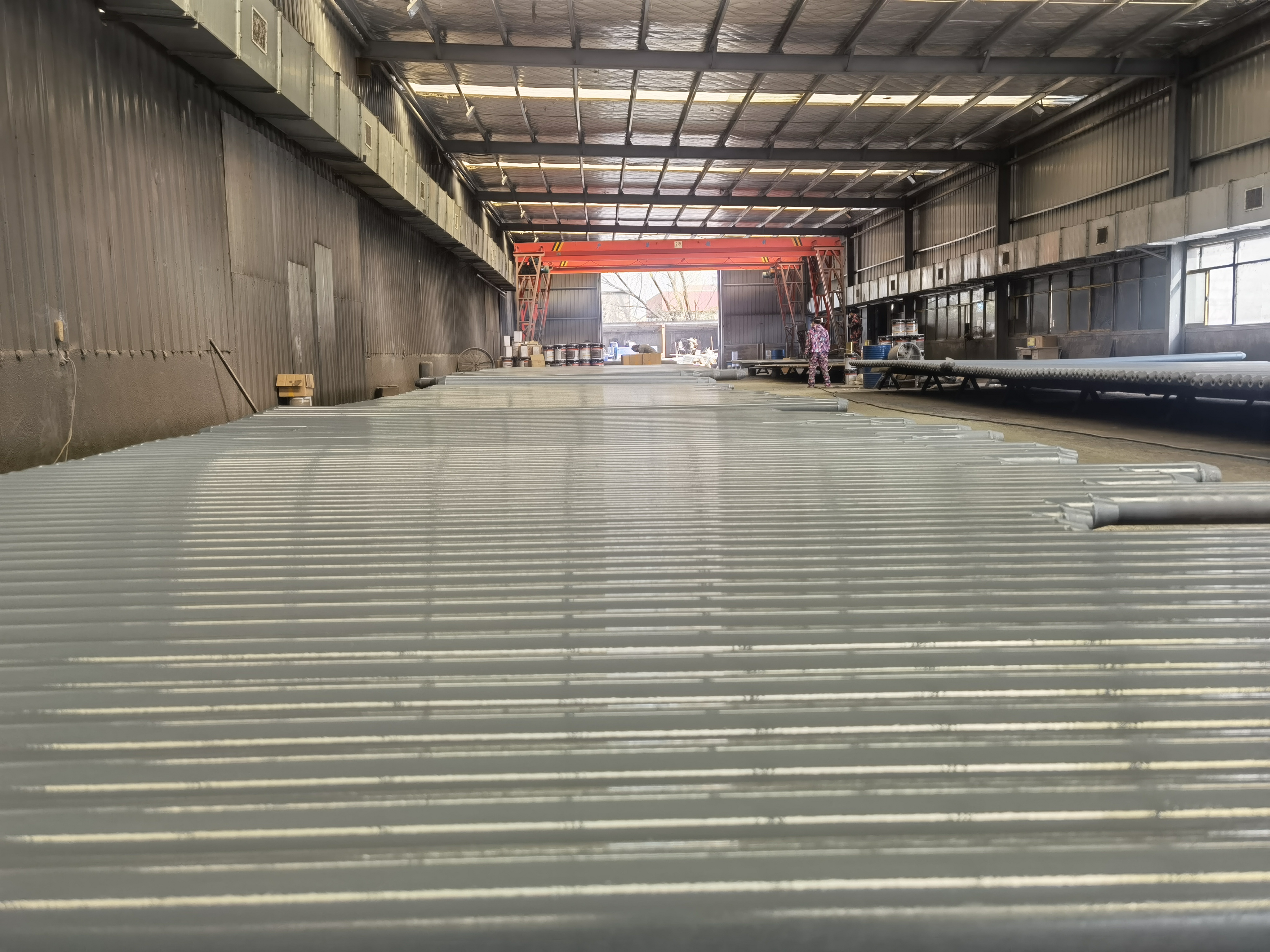

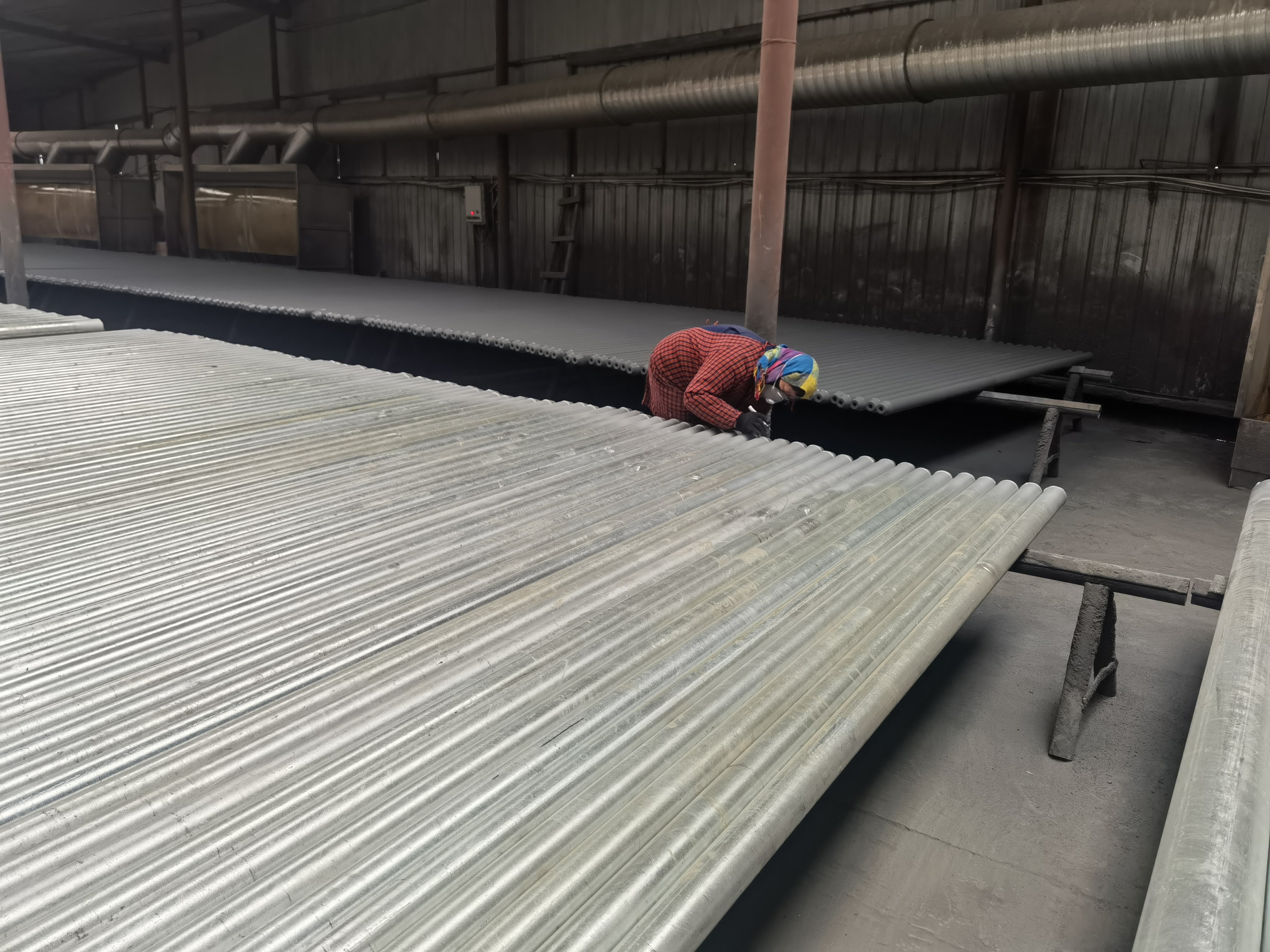

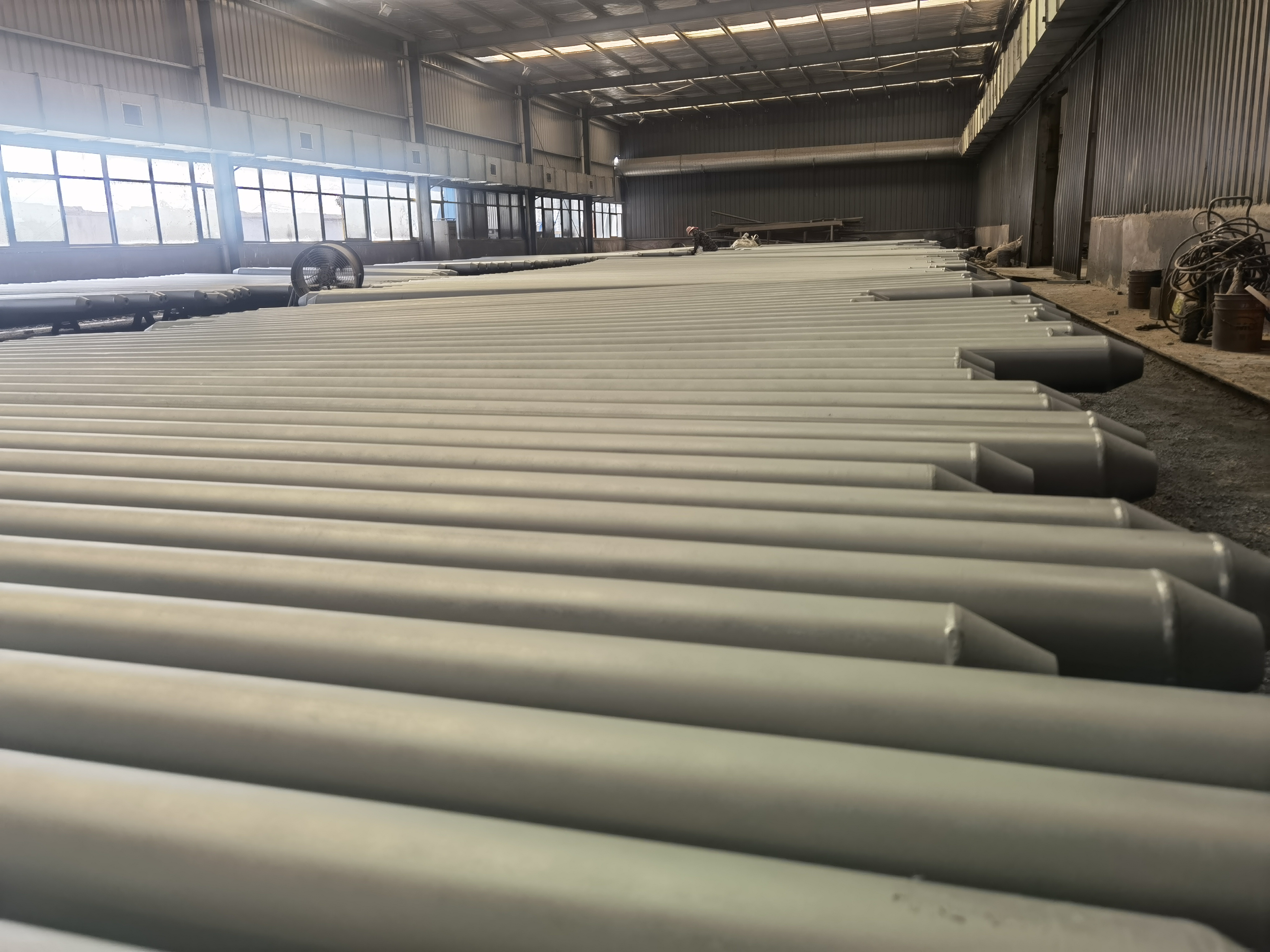

Shot blasting and derusting process of steel space frame

Shot blasting:

Shot blasting is to use the centrifugal force of the impeller on the shot blasting machine when it rotates at high speed, and the shot blasting process is very high.

The linear velocity of the steel is shot to the surface of the steel to be treated, resulting in a blowing and grinding effect, and the oxide scale on the surface of the steel is removed.

and rust, and produce a certain roughness. Shot blasting is highly efficient and can be performed in a sealed environment.

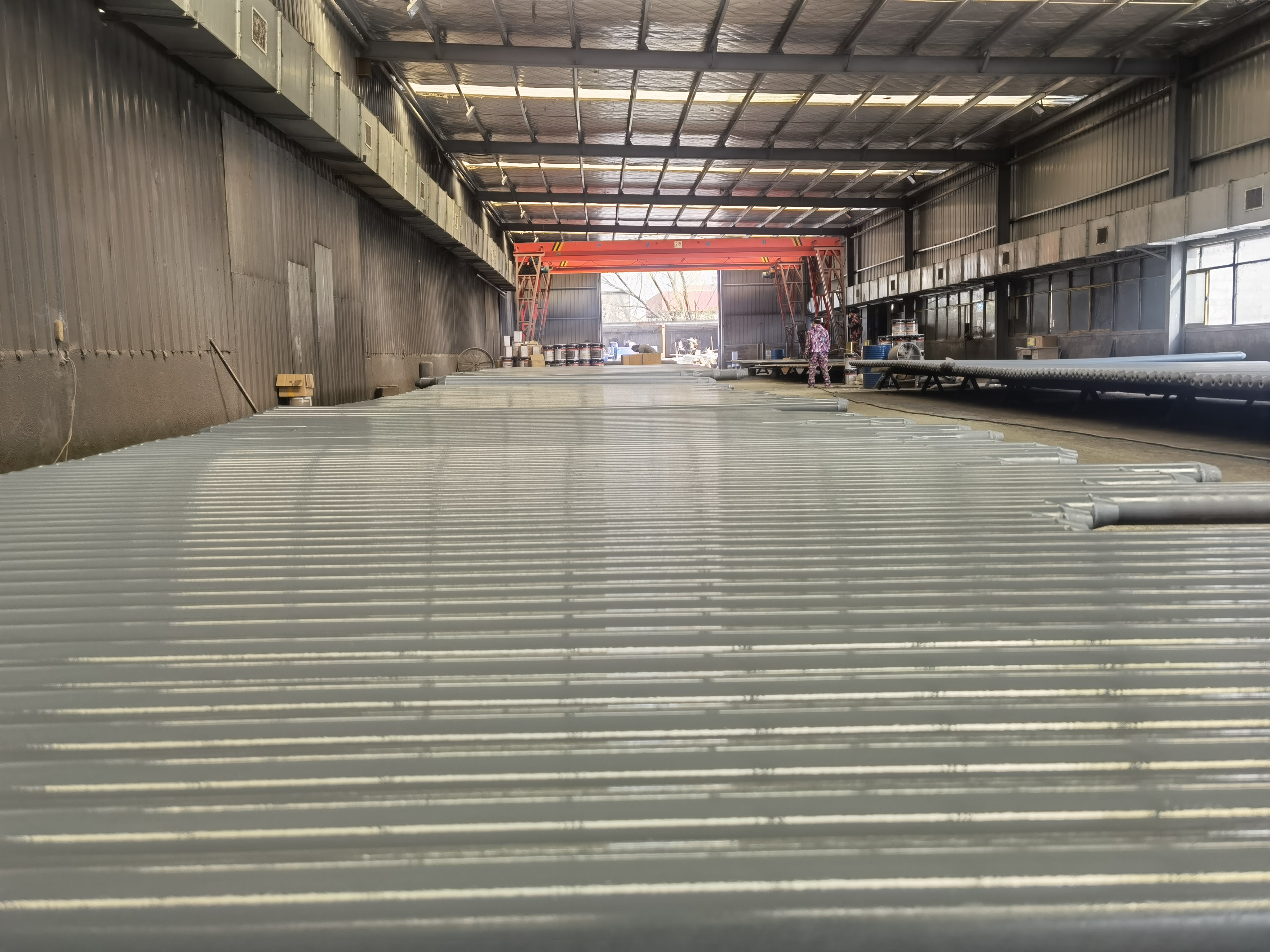

Shot blasting and rust removal grade;

(1) Mild shot blasting and rust removal. The steel surface should be free of visible grease or dirt and free of strong oxide scale, rust and paint coatings and other attachments;

(2) Thorough shot blasting and rust removal. The steel surface should be free of visible grease or dirt and free of strong oxide scale, rust and paint coatings and other attachments;

(3) Very thorough shot blasting and rust removal. The steel surface should be free of visible grease or dirt, scale, iron attachments such as rust and paint coatings, any remaining traces should be only slight stains in the form of dots or strips;

(4) Shot blasting and rust removal to make the steel surface clean. The steel surface should be free of visible grease or dirt, oxidation skin, rust and paint coatings and other attachments, showing a uniform metallic luster;