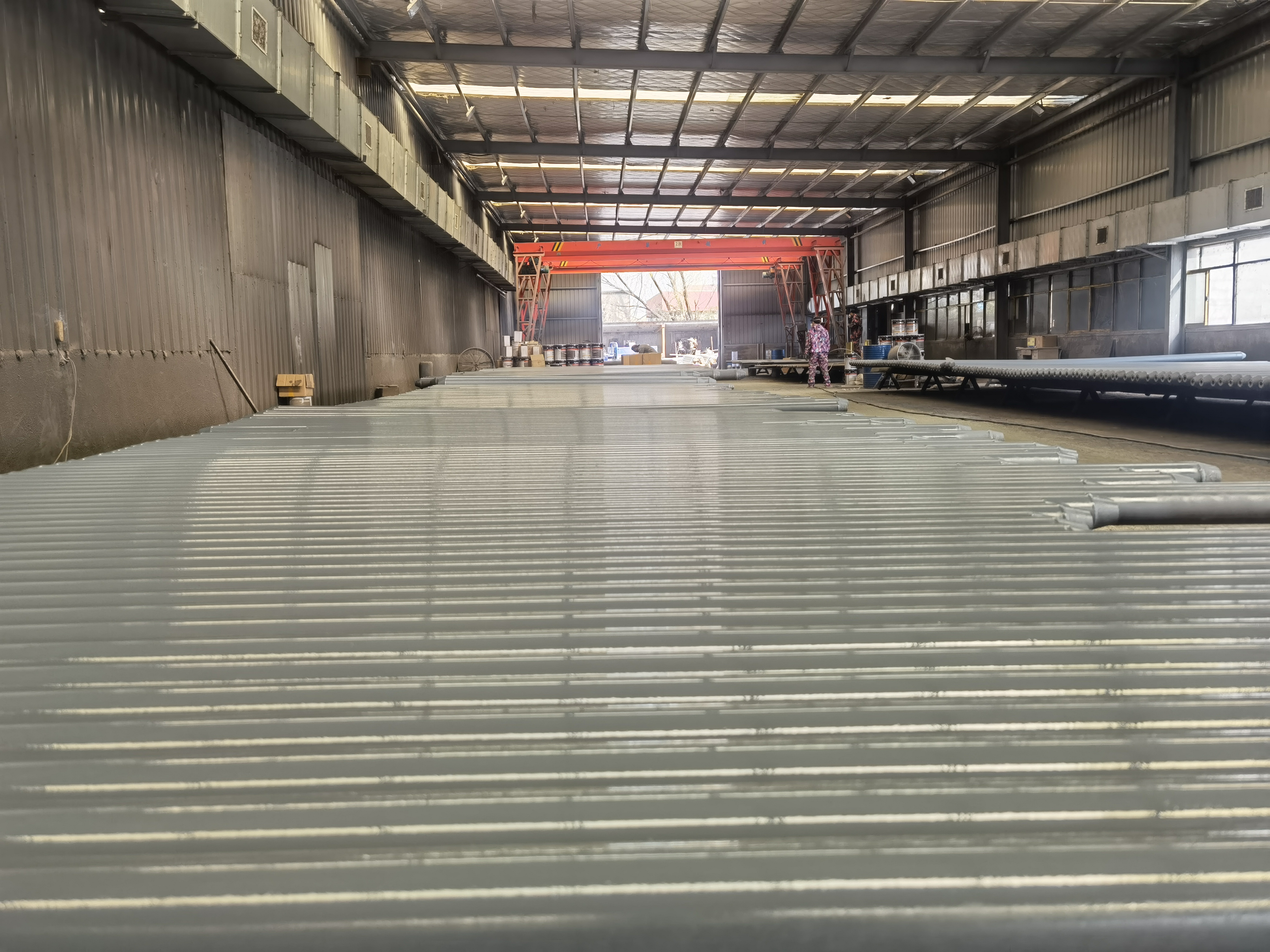

steel space frame painting process

Paint:

After the rust removal, the surface of the components should be cleaned immediately, and the anti-rust paint should be sprayed.

The requirements should be in accordance with the design regulations, and the painting process should be carried out according to the operation instructions and the corresponding varieties of paints and instruction manuals. The ambient temperature and humidity during painting should be controlled by a thermo-hygrometer to ensure that the requirements of the corresponding varieties of paint technology are met. The thickness of spraying It is checked and controlled by a thickness gauge, and the thickness of each paint should be controlled according to the instruction manual. After painting, a special person should make a mark according to the requirements of the drawings. The main marks of the components include the assembly number, the height reference point, the center line of the assembly reference line, and the hanging point.