OEM Supply Parking Shed Roof - Membrane structure processing – Puye

OEM Supply Parking Shed Roof - Membrane structure processing – Puye Detail:

Membrane structure processing and production process:

Membrane structure processing and production process:

1. After the membrane material is inspected, it should be transported into the clean workshop that has been dedusted.

2. Sampling 20 sets of diaphragm and back sticker samples, using a 60mm wide splicing knife to determine 4 groups of different splicing temperatures, currents, and pressing time. For the connection data of force and appearance, fill in the determined data and paste it on the connection machine, and the diaphragm connection is connected according to the data in this table.

3. The blanking of the diaphragm must go through three procedures in sequence: read the coordinates of the cutting design, take the point; review the coordinates, draw the material line; review the coordinates, drop the knife and blank the material. Then stick a numbered label and lift it to the stakeout area.

4. In the staking area, staking out all the diaphragms of the membrane unit that has been unloaded, and then draw the stitching line after checking. Use a soft cotton cloth when wiping the seam membrane and backing strip.

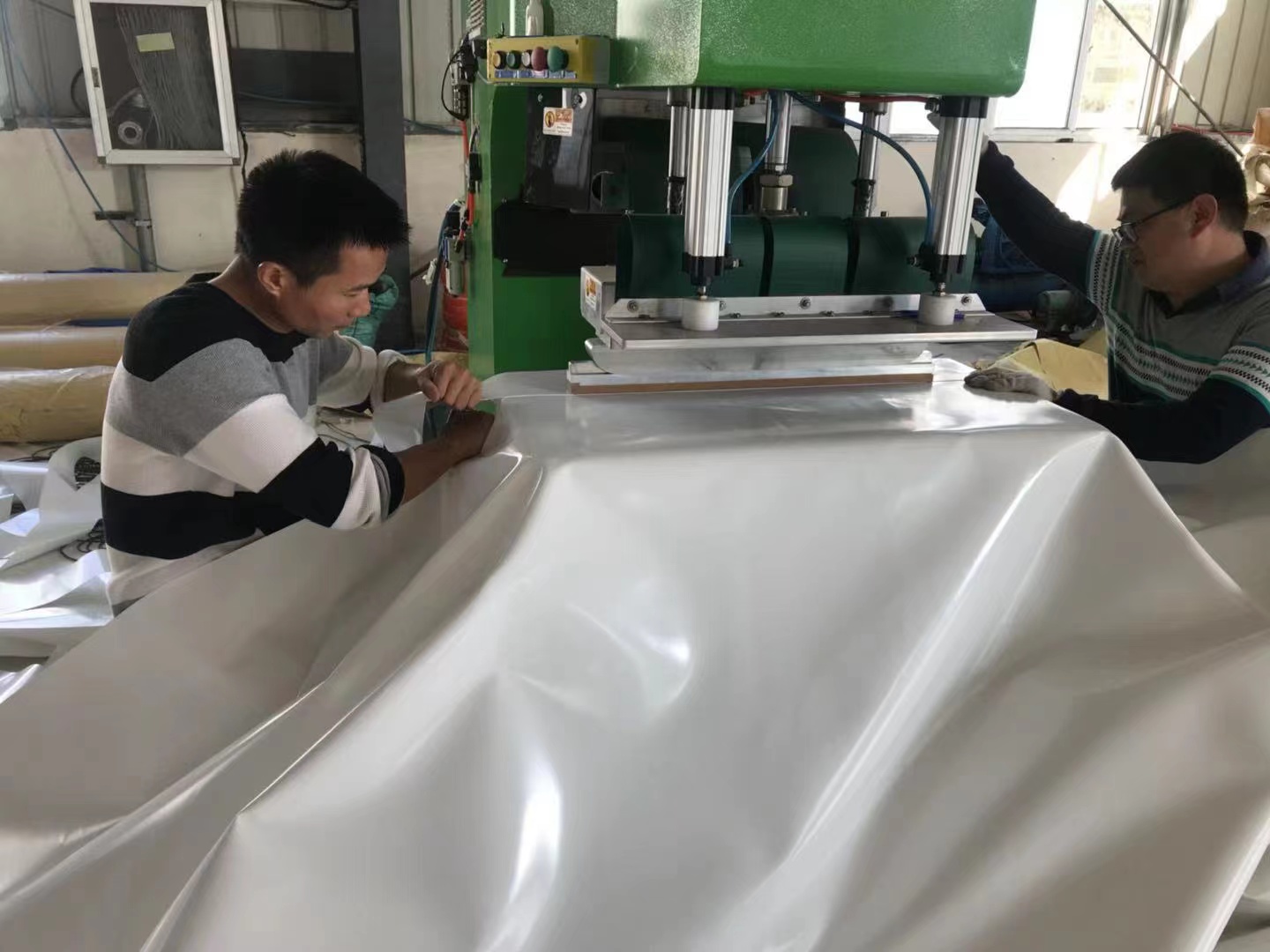

5. When connecting the machine, the back sticker is set on the bottom surface of the film. After the diaphragm and the connecting knife are centered, the diaphragm is flattened and stabilized, so that the diaphragm does not move during the high-frequency connection process.

6. The overweight membrane unit should be subdivided when splicing, and finally the splicing seam will be moved with a small crane and the membrane will be folded and packaged.

Specification:

describe:

1.Material: 100% polyester..

2. Finish: Use PVC coated tarpaulin.

3. Dimension: Diversity design, according to customer’s requirements.

Membrane structure processing site:

Product detail pictures:

Related Product Guide:

All we do is usually connected with our tenet " Customer to start with, Rely on initial, devoting on the food packaging and environmental protection for OEM Supply Parking Shed Roof - Membrane structure processing – Puye , The product will supply to all over the world, such as: Jamaica, Liberia, Turkmenistan, We have sufficient experience in producing products according to samples or drawings. We warmly welcome customers from home and abroad to visit our company, and to cooperate with us for a splendid future together.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.